centrifugal pump diffuser|volute casing in centrifugal pump : mail order This video describes the major parts and function of a centrifugal pump with a diffuser design and multi vane impeller. Resultado da Haz tus apuestas online en Betway, la mejor casa de apuestas. Regístrate hoy y disfruta de nuestro casino online y de una gran selección de .

{plog:ftitle_list}

Resultado da Like thousands of players who use VegasSlotsOnline.com every day, you .

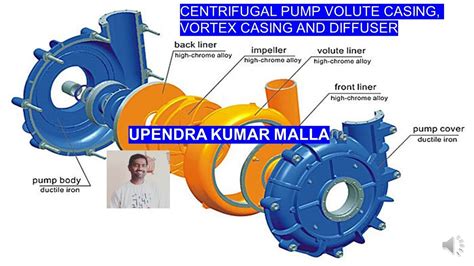

There two basic types of pump casings: volutes and diffusers. Whether we’re talking about volutes or diffusers, what all casings have in common is that they are designed to take energy in the form of velocity and convert it into pressure. .Especially for pumps made for operation at relatively low flow rates, diffuser pumps outperform volute pumps efficiency wise. In addition to the higher maximum efficiency, the efficiency does .The most critical decisions in the selection of a centrifugal pump for an application would be between a volute casing and a diffuser casing. Both casings have some individual .

This video describes the major parts and function of a centrifugal pump with a diffuser design and multi vane impeller.

Centrifugal pumps are the most common type of pumps found in DOE facilities. Centrifugal pumps enjoy widespread application partly due to their ability to operate over a wide range of .In centrifugal pump technology, diffusers are frequently used on the discharge side of ring-section and volute casing pumps (see Pump casing), they are also used in multistage .

diffuser and a high degree of variance in the velocity profile as flow enters the pump suction. The Flow Cone now directs the flow completely out of the suction diffuser and into the pump suction while also providing a more uniform velocity profile. As a result pump efficiency is more effectively retained and pumping system energy costs are .

,this video explain What is the difference between Volute and Diffuser centrifugal pumps ?VOLUTE AND DIFFUSER PUMPS Volute and diffuser describe the area in. For instance, Arndt et al. (1990) carried out measurements in both stationary and rotating channels of a centrifugal pump. In the vaned diffuser they found higher pressure pulsations on the suction side and increased unsteadiness for smaller gaps between impeller and diffuser vanes. Measurements in the impeller vanes revealed the largest .The casing of a pump is an important component in guiding the fluid through the pump, thus determining the overall efficiency and performance of the system. There are mainly two types of casings used in centrifugal pumps: volute casings and diffuser casings. Volute Casing. A volute casing is designed with a gradually flared, spiral-shaped .

A centrifugal pump is a rotodynamic pump that uses bladed impellers with a radial outlet to transfer rotational mechanical energy to fluid by increasing the fluid kinetic energy and increasing potential energy. . This cone-shaped discharge nozzle is also called a diffuser. During the reduction in velocity in the diffuser, energy in the flow .A Centrifugal pump means hydraulic machine that converts mechanical energy into hydraulic energy. It includes definition, parts, types, work. . Mainly used as wet pit pumps or diffuser pumps. The column is used as discharge. VS2 Type Pump. This kind of .Casing with Guide Blades or Diffuser Casing; READ Types of Condensers. The diffuser casing is a highly efficient casing in centrifugal pumps. Fig. 2: Pump Casing Types . A centrifugal pump is a mechanical turbomachine that converts mechanical energy into hydraulic energy through centrifugal activity and is used for transporting liquids. The .

This video describes the major parts and function of a centrifugal pump with a diffuser design and multi vane impeller.A diffuser is an air flow device designed primarily to discharge supply air into a space, mix the supply air within the room air, and to minimize unwelcomed drafts. From: Handbook of Green Building Design and Construction . Centrifugal Pumps, . A single-stage centrifugal pump with a radial diffuser was selected as the research model. The inner flow was simulated using the commercial computational fluid dynamics (CFD) program CFX and verified by experiment. The results indicate that the head and efficiency of the pump are best when the vane outlet angle is 6°. The flow area decreases .

The engineer has completed a detailed pump head calculation based on a piping system with a B&G Model HG-3 suction diffuser with an 8-inch system connection and a 6-inch pump connection. The Cv of this suction diffuser is 1050, which translates into a pressure drop of 2.1 feet at 1000 GPM.Some centrifugal pumps contain diffusers. A diffuser is a set of stationary vanes that surround the impeller. The diffuser directs the flow, allows a more gradual expansion, and therefore increases the efficiency of the centrifugal pump. Shaft (Rotor). The impeller is mounted on a shaft. A shaft is a mechanical component for transmitting torque .

Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. As illustrated in Figure 13, two identical centrifugal pumps operating at the same speed with the same volumetric flow rate contribute the same pump head. Since the inlet to the second pump is the outlet of the first pump . Particle image velocimetry measurements are used to identify the unsteady flow structures and turbulence in a transparent centrifugal pump with a vaned diffuser. The experiments are being performed in a special facility that enables simultaneous measurements of the flow between the impeller blades, the gap between the impeller and the diffuser, between .Centrifugal pumps represent an integral part of our life today. They are primarily used for moving liquids from one place to another using an energy conversion process. . flowing radially outward into a diffuser or volute chamber (casing), from where it exits into the downstream piping system[^1^]. [^1^]: Industrial Flow Measurement, David W .A centrifugal pump diffuser according to claim 1, wherein: adjusting part is including welding connection otic placode (101) at diffuser blade (3) lateral wall, and connection otic placode (101) and regulation otic placode (4) set up relatively to and support otic placode (102) at diffuser roof (2) top through the bolt fastening, the lateral .

the following page is an illustration of a single end-suction centrifugal pump piping arrangement typi- . view of a typical diffuser attached directly to a pump suction. Manufacturers of suction diffusers state that they can be utilized to smooth, balance, and otherwise streamline liquid flow to the impeller eye when physical space is . A centrifugal pump is a hydraulic machine designed to transport fluids by converting rotational kinetic energy into hydrodynamic energy. . The housing that surrounds the impeller. Two main types of casings exist – volute and diffuser. Volute casings have a curved shape, helping increase fluid pressure as the fluid flows. Some centrifugal pumps contain diffusers. A diffuser is a set of stationary vanes that surround the impeller. The diffuser directs the flow, allows a more gradual expansion and therefore increases the efficiency of the centrifugal pump. Shaft (Rotor). The impeller is mounted on a shaft. Shaft is a mechanical component for transmitting torque .

The optimum designs of the centrifugal pump predicted by the surrogate models show considerable increases in efficiency compared to a reference design. Performance of the best optimum design was validated compared to experimental data for total efficiency and head. . Analysis and optimization of a vaned diffuser in a mixed flow pump to . The hump characteristic is generated by a surge of hydraulic loss in the pump under part-load conditions, which is considered by Gülich [8] to be closely related to sudden changes of flow pattern in the pump.In centrifugal pumps, the increased instability of multiple flow patterns in the hump region is observed by scholars, including leakage flow, backflow, .By converting kinetic energy into pressure energy, the diffusers in a multistage centrifugal pump enable the pump to operate at higher pressures and deliver fluids to greater distances. Without the diffusers, the pump would not be able to achieve the necessary pressure rise and would be limited in its application. Therefore, the proper design .

The two main types of casings in centrifugal pumps are volute casings and diffuser casings. Diffuser Casing. A very common classification of pump casings is the diffuser construction. A diffuser is actually a series of vanes surrounding the impeller which accepts the discharge of liquid from the impeller. It efficiently reduces the velocity and .Keywords: CFD, Centrifugal pump, Impeller-diffuser interaction, Numerical simulation Introduction Effects of individual variables, including number of impeller blades, inlet diameter, and impeller exit width, on pump performance are difficult to predict from empirical rules1. Miner et al2 found that distribution of relative velocity components .

Centrifugal pump is a mechanical machine that pumps fluid by converting mechanical power into pressure energy using a centrifugal force acting on the fluid. . This pump uses an impeller and a volute casing or diffuser to pump the fluids. The impeller is connected to an engine or electric motor. A centrifugal pump works in the following way:centrifugal pump having 6 impeller blades, 8 diffuser vanes, and 11 return guide vanes. The diameter of the impeller is 412 mm. The height of the impeller blades and diffuser vanes is 23 mm and of RGV is 35 mm. In multistage centrifugal pump, impeller is a rotating components, whereas diffuser and return guide vanes are stationary components. The centrifugal pump diffuser is composed of Q345B steel. The main composition and content of standard Q345B steel are shown in Table 1. We have tested the base material composition of experimental centrifugal pump diffuser, and the result is shown in Table 2. The Table 2 indicates that the base material of the centrifugal pump diffuser used in .

volute vs diffuser casing

volute casing in centrifugal pump

single volute vs double pumps

web28 de set. de 2020 · Oasis - Champagne Supernova (Official Video) [HD Remastered]Oasis' iconic album (What’s The Story) Morning Glory? turned 25 on 2nd October 2020! To celebrate.

centrifugal pump diffuser|volute casing in centrifugal pump